Electronic Backscatter Diffraction mapping

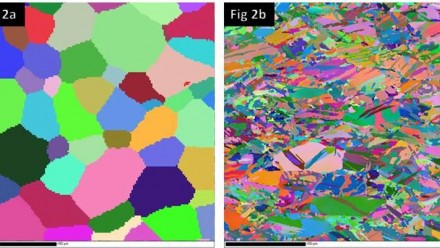

Figure 2a. EBSD map of an undeformed Titanium sample. Figure 2b. EBSD map of a Titanium sample after deformation by a compressive force.

Figure 2a. EBSD map of an undeformed Titanium sample. Figure 2b. EBSD map of a Titanium sample after deformation by a compressive force.

Figure 3a: Highlighted twin boundaries in Ti after deformation by compressive force with ultrasonic vibration (Green , Red ). Length fraction of twinning boundaries to the high angle grain boundaries (>15 Deg.) is 7.4%.

Figure 3a: Highlighted twin boundaries in Ti after deformation by compressive force with ultrasonic vibration (Green , Red ). Length fraction of twinning boundaries to the high angle grain boundaries (>15 Deg.) is 7.4%.

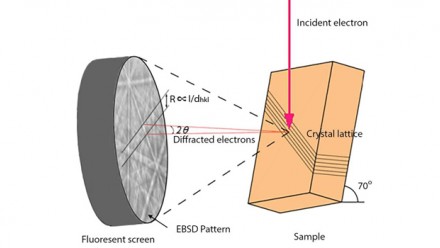

Electron Backscatter Diffraction (EBSD) is a technique available in the SEM whereby a focused electron beam impinges on a highly inclined (70°) crystalline surface (Figure 1).

The diffracted electrons form an EBSD pattern which is captured on a fluorescent screen. Each pattern is unique to a specific crystal structure as well as its orientation relative to the sample surface. Analysis of the such EBSD patterns can therefore be used to provide information on a wide range of microstructural aspects of crystalline materials, including texture, deformation, grain size distribution and defects.

The use of EBSD in the investigation of ultrasonic vibration assisted compression of titanium metal

The introduction of ultrasonic vibration during plastic deformation leads to a decline in the flow stress during compression, known as ultrasonic softening. The benefit of such a treatment can lead to grain size reduction and the enhancement of fatigue properties. The ZEISS Ultraplus FESEM, equipped with an Oxford Instrument (HKL EBSD) system was used to collect grain orientation maps and investigate the microstructure of the deformed titanium samples.

Owing to the hexagonal close packed (hcp) arrangement of titanium, slip systems for stress relief during plastic deformation are limited. As a result the primary deformation mechanism in titanium is largely due to deformation induced twinning. Ultrasonic treatment during deformation initially leads to an increase in the development of twinning boundaries. As the twinning boundaries reach saturation however, the twins start to subdivide leading to a reduction in the number of twinning boundaries. The EBSD maps shown in figures 2a and 2b depict examples of the microstructures of the titanium both before and after deformation. It is clear that there is a significant change in overall grain shape and size after compressive deformation. Figures 3a and 3b show EBSD maps of deformed titanium with and without the application of ultrasonic vibration, where only the <10-10> (green) and <11-20> (red) type twins have been highlighted. It is obvious that there is a substantial reduction in the number of twinning boundaries in the ultrasonically treated sample (approx. 5 times less) relative to the sample deformed without ultrasonic treatment.

Extracted from 'A comparative study of mechanical and microstructural characteristics of aluminium and titanium undergoing ultrasonic assisted compression testing

Haiyang Zhou, Hongzhi Cui, Qing-Hua Qin, Hui Wang, Yaogen Shen

Materials Science and Engineering: A, Volume 682, 13 January 2017, Pages 376–388